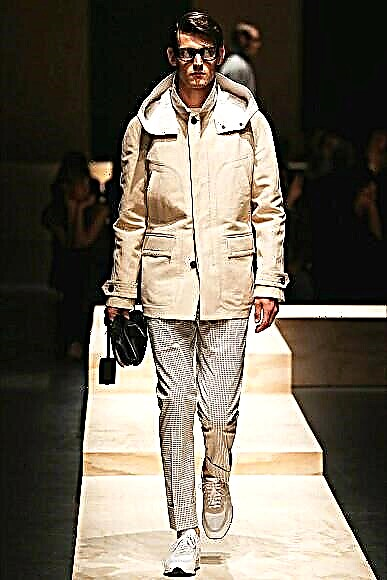

There are several tailor schools of classic men's wardrobe, one of them is Italian, and has long been confidently in the lead.

Grace in Italian art, architecture, cuisine and even lifestyle is reflected in clothing. A special cut, original processing techniques allow you to create not only comfortable and practical, but also elegant clothes.

Italian costumes are usually tailored exactly to the shape. Trousers are made narrower, they are not collected by horizontal folds at boots. The sleeve of the jacket allows you to see the cuff of the shirt (as well as cufflinks and watches). The shoulders of the jacket emphasize posture. They can be sloping in the Neapolitan style, with soft folds around the sleeves, or crisp and strict in the Roman style. It is always a nifty look with a touch of casual chic.

A shirt for such a suit should have a semi-adjacent silhouette, with a high armhole, which gives maximum freedom of movement of the hands. Often, for a more comfortable fit, the shoulder of the shirt is shortened, and the height and width of the okata of the sleeve are increased. By the sleeve’s circumference, a landing is obtained, which is laid in small folds. This technique allows you to bring the cut closer to the anatomical and reduce the amount of increase in freedom of fit.

Gusset processing in a men's shirt using Vincent Smith technology

In the first part of this master class, we will consider the processing of the section of the sleeve cut and the preparation of the sleeves for embedding, and in the second - the Neapolitan cuffs and opening the armholes manually.

As a basis, you can take one of the patterns of fitted shirts from the Burda Fall-Winter 2015/2016 catalog:

- Best-seller

- Special offer

- 1

- 2

- 3

- 4

- Best-seller

- Special offer

- 1

- 2

- 3

- 4

Step 1

Cut out the details of the sleeves with allowances at the bottom 1.0 cm, around the sleeve 1.5 cm, along the front cut of the sleeve 1.5 cm, along the back cut of the sleeve 0.7 cm.

Important:

If the shared thread on the details of the yoke made of fabric with a pattern (cage or strip) runs along, then the pattern should clearly coincide at the point where the sleeve is sewn in. To achieve the best result, focus on the marks of the shoulder seam on the parts of the coquette and the top of the okat on the details of the sleeves.

If the fabric has an asymmetric pattern, then the sleeves must be cut into a fabric turn.

Handle Closure Processing

Step 2

Make a vertical cut on the details of the sleeves 13-16 cm long (the cut location is indicated on the pattern).

Cut out strips and details of slats for processing the section of the sleeves. The necklace can be cut along the oblique (at an angle of 45 'to the warp thread) or along the share. The width of the inlay is 3.5-4.0 cm, and the length is equal to the length of the cut plus 0.5 cm. Cut the planks along the share. The width of the detail of the strip is equal to its two widths in the finished form, plus 2.0 cm for processing, the length is equal to the length of the cut plus 4.0–5.0 cm. Typically, the width of the strip in the finished form is 2.0–3.0 cm

If the fabric has a pronounced pattern (cell, strip), then the details of the strips and strips should be cut taking into account the horizontal and vertical rapport of the pattern.Thus, the top of the plank and the outer fold of the inlay should fall on that part of the pattern along which the cut on the sleeve passes.

Note: further on the photos, for clarity, both share and oblique bei will be shown. The processing principles do not change.

Step 3

Iron the bales along the part with the wrong side inwards, then bend the open sections to the fold and fix with an iron.

Step 4

To iron the bar details, you need to prepare a cardboard template as in the illustration above. The length and width of the template corresponds to the size of the strip in the finished form. Next, place the template on the wrong side of the plank, its top is located on the fragment of the picture, which falls on the cut. Be especially careful when working with fabrics that have an asymmetrical strip or cage! Alternately iron the corners of the bar detail onto the template. Then iron the bar detail along, guided by the width of the template.

Iron the longitudinal sections of the bar part inward one at a time. It is best to perform this operation in parallel on both parts of the bar.

The details of the bar must be mirrored.

Step 5

Make a transverse notch at the top of the sleeve section towards the bottom of the fastener. The length of the notch is equal to the width of the ironed inlay. Bast and stitch inlay on the bottom of the sleeve section. The transverse edge of the inlay should extend 0.5 cm beyond the notch and be located on the front side of the fabric.

Note: the stitch frequency when sewing high-grade men's shirts should be 8–9 stitches per 1 cm. Experiment with the settings of your sewing machine, the stitch length should be set to approximately 1.4 mm. Needles for the sewing machine should be very thin - No. 60−70. Threads are also needed thin, for example, Madeira No. 120 or their corresponding thickness.

How to properly perform wet-heat treatment of men's trousers

Step 6

Insert the second untreated side of the sleeve cut into the strap. The top and edge of the cut must be combined with the ironed cut of the stock allowance and sketched.

Then cover the slice with the outer side of the plank, lay the second basting line along the cut and then along the contour of the top of the plank.

Step 7

Position the sleeve with the wrong side up, put a mark with a pin or thread of contrasting color in the place of the transverse notch of the sleeve cut. 0.1 cm from this point should pass machine transverse tack.

Step 8

Lay a single machine line 0.1-0.2 cm from the edge of the bar, turning the sleeve part, from the bottom of the sleeve to the fastening mark.

Then, without interrupting the line, cross-tack the entire width of the plank.

Processed plank: view from the front and the wrong side.

Preparation of sleeves for embedding

Step 9

Observe and iron the allowance along the bore of the sleeve on the front side to a width of 0.5 cm.

Sweep the lower seam of the sleeve, releasing an allowance of 0.7 cm from the front of the sleeve. In the future, this difference will be needed to make the seam.

Stitch the lower seam of the sleeve with a stitch width of 0.7 cm.

Iron the seam allowance on the back of the sleeve. Bend the edge of the wide allowance, rounding the narrower one. Sew a seam.

Sewing seam in finished form.

How to sew sewing in a man's shirt

The bent edge of the allowance can also be sewn manually with hidden stitches. In addition, Italian craftsmen strive to make the width of this seam as narrow as possible, in some cases it reaches 3 mm. To make such a narrow seam, it is necessary to carve seam allowances up to 3 and 6 mm, respectively.

Continuation of the master class in the second part:

Neapolitan cuffs and openings armhole in a man’s shirt

The author of the master class and photo: Elena Lenkova

Lena has a higher and special education - a tailor of outerwear for men, women and children.

In clothes, he appreciates the individuality and thoughtfulness of the image, the originality of the cut. He likes to analyze modeling techniques and product processing technology. Leads his page on Instagram.Many people know Lena as a longtime user of the BurdaStyle.ru website.

"The quality of processing and the interior decoration of the product are integral aspects of sewing."

Material prepared by Julia Dekanova